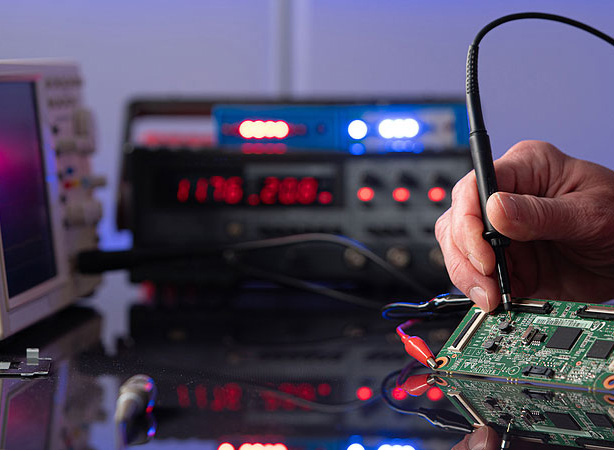

PCB board testing is mainly used to alleviate problems throughout the entire manufacturing process and the final production process. These types of tests can also be used on prototypes or small-scale assemblies, which helps identify potential issues that may exist in the final product.

PCB board testing

What are the items of PCB board testing?

1. Slice analysis

Test purpose: Plating copper thickness; Test the roughness of the hole wall; Dielectric layer thickness; Thickness of anti-welding green oil.

Test method: Slice and analyze the metalized holes on the PCB board tesing.

2. Green oil adhesion test

Test purpose: To test the adhesion between the anti-welding paint and the board or circuit surface.

Test method: Apply 600 # 3M tape tightly to the green oil surface of the PCB, with a length of about 2 inches. Apply the adhesive surface three times by hand to ensure it is flat. The tape can only be used once at a time. Quickly pull up the tape perpendicular to the board surface by hand, and check if the tape is attached with anti-welding paint, and if there is any looseness or separation of the anti-welding paint on the board surface.

3. Metallized hole thermal stress test

Test purpose: To observe whether there is damage to the interconnections within the metalized holes and whether there is the layering of the glass cloth substrate.

Test method:

1) Place the sample PCB in an oven and bake at 150 ℃ for 4 hours. Take out the sample and let it cool to room temperature.

2) The sample PCB was completely immersed in the tin solution for 10 ± 1 seconds per time in a tin furnace at 288 ℃± 5 ℃. After cooling, it was taken out and subjected to a second test, totaling 3 times. After removing the sample, let it cool and clean it thoroughly.

3) Perform hole slicing (slice analysis based on minimum aperture and PTH hole). Use a metallographic microscope to observe the section inside the hole.

4. Dielectric withstand voltage test

Test purpose: To test the insulation performance of circuit board materials and whether the space between wires is sufficient

Test equipment: withstand voltage tester

Test method:

1) Select 2 sets of test objects on the PCB board testing, including adjacent wires on the same layer and between adjacent layers, respectively led out through flexible wires

2) Before the experiment, bake the board at a temperature of 50-60 ℃/3 hours and cool it to room temperature

3) Connect the withstand voltage tester to the test line on the tested PCB board separately

4) Increase the voltage value from 0V to 500VDC (two layer board 2000V), and the boosting speed should not exceed 100V/s

5) Under the action of a voltage of 500VDC, the duration is 30 seconds

Acceptance standard: During the testing process, there should be no arcing, flash, breakdown, or other situations between the insulation medium or conductor spacing.

5. Damp heat and insulation resistance test

Test purpose: To detect the degree of decrease in insulation resistance of printed boards when exposed to high humidity and heat conditions.

Testing equipment: voltage withstand tester, damp heat box, DC voltage source

Test method:

1) Select test points: Select 2 sets of test objects on the PCB board testing, including adjacent wires on the same layer and adjacent layers, and lead them out through flexible wires (the same as selecting test objects for the dielectric withstand voltage test)

2) Pre-test testing: The specified test voltage of the product should be applied in the standard laboratory environment, and the insulation resistance between test points should be measured. During the testing, the positive and negative polarity should alternate, and the results of two tests should be obtained.

6. Temperature impact test for printed boards:

Test purpose: To test the physical endurance of printed boards during sudden temperature changes

Testing equipment: million meters, high and low heat box, slicing analysis tool

Test method: Before the experiment, select two sets of printed board wires on the printed board and measure the wire resistance

Set two temperature chambers to work at high and low-temperature points according to the following temperatures. After the test time is reached, manually transfer the sample between the two temperature chambers within the conversion time.

Acceptance criteria:

1) The test resistance at three-time points before the test, the first and last thermal cycle, and the change in resistance before and after the test shall not exceed 10%

2) After the experiment, at least three metalized holes should be selected for slicing analysis on each printed board to observe whether the interconnections inside the metalized holes are damaged and whether there is the layering of the glass cloth substrate.

PCB board testing methods

1. Online testing

Online testing requires the use of online testers, fixtures, and specialized software. This device can be used together and directly interact with the tested board, while the software can guide the system and provide testing for each type of board.

This method is popular because it can identify 98% of faults and can test individual components independently of any other components it is connected to.

2. Flying Needle Test

Flying needle testing, also known as fixture-free online testing, can run without the need for any custom fixtures. Its main advantage is that it can minimize the total cost of testing, but it is also very simple.

This test uses a fixture to fix the circuit board so that the test pins can move and analyze various points, all of which are controlled by software. It has a wide range of applications and can quickly and easily adapt to new circuit boards.

3. Automatic Optical Inspection (AOI)

AOI testing will use one 2D camera to two 3D cameras to capture photos of PCBs. Then, the program will compare these images with detailed schematic diagrams to find defects or mismatches.

AOI can be used to identify early issues to stop production and save time and money. However, experts will never rely solely on AOI just because it cannot power up circuit boards and test all part types.

4. X-ray examination

Technicians use X-ray inspection (AXI) to locate defects in solder connections, internal wiring, and gun barrels. With the help of 2D and 3D AXI testing, designers can choose based on the blocks at hand - although 3D testing is usually faster.

5. Functional testing

Functional testing is very simple because it only tests the functionality of the circuit. The function test is used at the end of the manufacturing plant. It is connected to the PCB through the test probe point or edge connector to simulate the final environment of the PCB.

6. Manufacturing Design (DFM)

DFM arranges PCB topologies related to the manufacturing process. It tests silver and islands, solder bridges, and copper on the edges - everything that can cause circuit board short circuits, corrosion, and interference.

DFM testing is typically used early in the process to help reduce overall costs and schedules. They use various software programs to maintain success.

7. Solderability test

As mentioned earlier, solderability is crucial for the construction process of PCBs. Solderability testing will ensure that the surface of the PCB is strong enough to form a solid and reliable solder joint.

8. PCB contamination test

This test identifies large ions that may contaminate the PCB board testing. These pollutants can cause serious problems, such as corrosion, and should be detected and eliminated as soon as possible.

9. Microsection analysis

Microsection testing will provide a professional understanding of defects, open circuits, short circuits, and any other types of faults.

10. Other functional tests

Other functional tests will determine the behavior of PCBs in the final product usage environment.

11. Time domain reflectometer

This test, also known as TDR, is used to locate faults on the high-frequency board.

12. Peel test

The peel test analyzed the strength and resilience of the laminates used on the board. It will determine the amount of force required to peel off the laminate.

13. Solder Float Test

Float welding tests use extreme temperatures to measure the level of thermal stress that PCB holes can withstand.

Through PCB board testing, significant issues can be minimized, minor errors can be identified, time can be saved, and overall costs can be reduced.