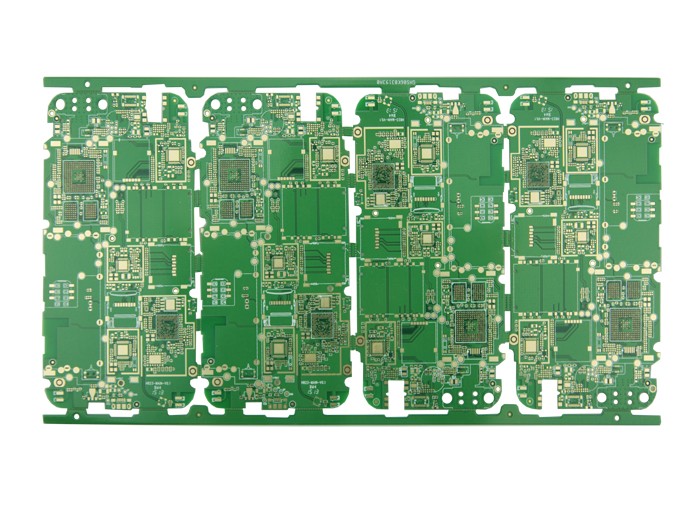

PCB electrical measurement technology analysis

1. Electrical test

In the production process of PCB boards, it is inevitable that electrical defects such as short circuits, open circuits, and leakage due to external factors will inevitably be caused. In addition, PCBs continue to evolve toward high density, fine pitch, and multiple levels. Screening out, and allowing it to flow into the process, will inevitably cause more cost waste. Therefore, in addition to the improvement of process control, the improvement of testing technology can also provide PCB manufacturers with solutions to reduce the rejection rate and improve the product yield. .

In the production process of electronic products, the cost of defects caused by defects has different degrees in each stage. The earlier it is discovered, the lower the cost of remediation.

"The Rule of 10's" is often used to evaluate the cost of remediation when PCBs are found to be defective at different stages of the process. For example, after the blank board is produced, if the open circuit in the board can be detected in real time, usually only need to repair the line to improve the defect, or at most one blank board is lost; but if the open circuit is not detected, wait for the board to be shipped When the downstream assembler completes the installation of the parts, the tin and IR are also remelted, but at this time it is detected that the circuit is disconnected. The general downstream assembler will ask the empty board manufacturing company to compensate for the cost of parts and heavy work., Inspection fees, etc. If it is even more unfortunate, the defective board has not been found in the test of the assembler, and it enters the whole system finished product, such as computers, mobile phones, auto parts, etc. At this time, the loss discovered by the test will be the empty board in time. A hundred times, a thousand times, or even higher. Therefore, for the PCB industry, electrical testing is for early detection of circuit functional defects.

Downstream players usually require PCB manufacturers to perform 100% electrical testing, and therefore they will reach agreement with PCB manufacturers on test conditions and test methods. Therefore, both parties will first clearly define the following matters.