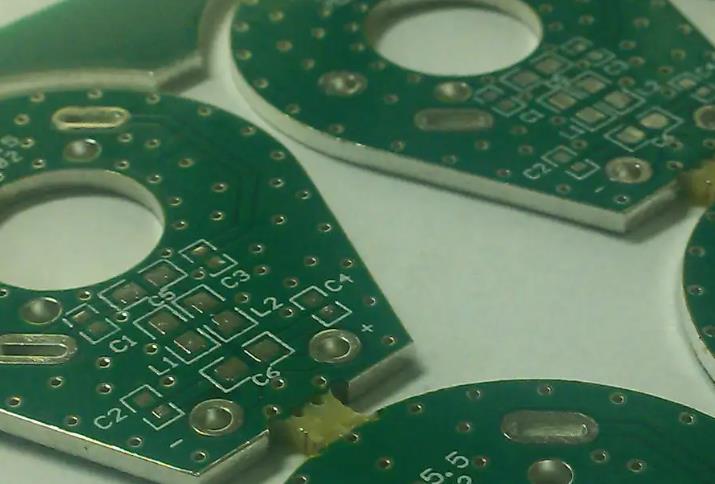

With the rapid advancement of the PCB industry and the continuous introduction of special components, surface packaging components tend to be miniaturized and multifunctional, which promotes printed circuit board design and printed circuit board manufacturing technology to become more dense, reliable and The high-precision direction is developed to meet the development and needs of miniaturization and multi-functionalization of electronic products. And PCB products are also developing rapidly in the direction of ultra-thin, small components, high density, and fine pitch. The assembly density of components on circuit boards has increased, and the line width, spacing, and pads of PCBs have become smaller and smaller, reaching the micron level, and the number of composite layers has increased. Traditional manual visual inspection (MVI) and bed of needle online testing (ICT) inspections are made by "restricted contact" (restricted electrical contact and restricted visual contact), and can no longer fully meet the needs of today's manufacturing technology development. It is usually necessary to drill holes of various sizes on the PCB, and the geometric size and position of the round holes after processing will affect the subsequent assembly process with IC components and other electronic devices.

On the other hand, due to the large number of round holes on the PCB, the traditional MVI and ICT technology can no longer adapt to such a rapid process. Based on the requirements of productivity and quality, it is extremely necessary to have a fast and precise detection method. In view of this, the development of a fully automatic optical image detection system for the PCB circuit board industry to monitor and ensure the quality of the production process has become an inevitable demand for the PCB board manufacturing industry.

1. Introduction to optical image measurement system

The American Micro-Vu company is a professional measuring instrument manufacturer for more than 45 years. It has an annual output of more than 1,500 sets and sells it to the world. It has a software team developed in cooperation with IBM and Microsoft. It is particularly well-received by various industries for its automatic measurement models and continues to innovate. Convenient and user-friendly, it can be accurately measured under different magnifications/different light sources. It is well-known in the world and the industry, and it is the largest visual measurement manufacturer in the United States.

2. The role of optical image detection system

The optical image measurement system is a key equipment of modern manufacturing machinery, and is widely used in machine vision applications, such as inspection, reverse engineering and other automation industries. With the development of high-tech industries, many product inspection methods in the past have now been required to be inspected by automated and non-contact methods. Taking the PCB industry as an example, the role of the optical image inspection system is to detect the size specifications of the PCB during the manufacturing process, perform process control, and eliminate or reduce defects by correcting the process. Usually the optical image detection system is placed in a key position to monitor the specific production status and provide the necessary basis for the adjustment of the production process.

In the PCB manufacturing process, items that need to be tested: film thermal expansion and contraction detection, product appearance detection, position detection of various elements, length, width and height detection, straightness detection, roundness detection, hole burr detection, etc.

3. Block diagram of optical image detection system

The optical image detection system is mainly composed of four parts: workbench, drive control, CCD camera system and software system.

4. The working principle of the optical image detection system

Automatic optical image detection system, the core structure is a set of CCD camera system, AC servo control x, y workbench and image processing system. When performing inspection, first place the printed circuit board to be inspected on the work surface of the optical measurement system, after positioning, call out the inspection program of the product to be inspected, the x and y workbenches send the circuit board under the lens, and the lens captures After reaching the image of the circuit board, the processor will move to the next position on the x and y workbenches to capture, and then perform corresponding calculations. Through continuous processing of images, a higher detection speed can be obtained. The optical image inspection system automatically regulates the size of the PCB through the program, and can input the actual value and tolerance that needs to be measured. After analysis, processing and judgment, the defect is found and the position is prompted, and the file is generated at the same time, waiting for the operator to further confirm or send it to the relevant department Make improvements.

5. The workflow of the optical image inspection system

The working flow diagram of the optical image detection system.

6. How does the optical image measuring system measure height

Since the emergence of various micro-via technologies in 1995, the industry has gradually adopted CO2 lasers, UV/YAG lasers, and optical imaging dielectric materials in mass production lines. These new technologies have led to changes in circuit board design thinking. The use of 0.3mm through holes is converted to a large number of blind holes and micro through holes, especially in high-density applications (such as mobile phones, computers, various boards and IC packages). Holes with an aspect ratio greater than 8:1 and a diameter less than 0.3mm have become more and more common, especially on the circuit boards of servers, substrates and workstations. How to control the quality of this type of through hole?

The principle of the optical image measuring system to measure height is to find the focal length difference between the two clearest surfaces at different heights. From the perspective of physical optics, the so-called "clear" is imaging between one and two focal lengths. That is to say, in a certain section, the imaging is clear, and when the difference between the focal lengths of the two surfaces during autofocus is accumulated, the accuracy of the Z axis cannot be compared with the X and Y axes. This requires a good control and technology, and the software must have a high technical content. The Micro-Vu measuring instrument adopts the software jointly developed with IBM and Microsoft. The light source can be adjusted arbitrarily in forty blocks in five circles and eight directions, and the Z axis The accuracy can also be controlled at about 5um, which is beyond the reach of other software.