1. What are the components and main functions of PCB circuit board manufacturers?

The PCB is made of different components and a variety of complex technological processes, among which the structure of the PCB circuit board has a single-layer, double-layer, and multi-layer structure, and the production methods of different hierarchical structures are different. This article will introduce in detail: the component names and corresponding uses of PCB circuit boards, the production of single-layer, double-layer, and multi-layer structures of PCB circuit boards, and the main functions of various types of work levels.

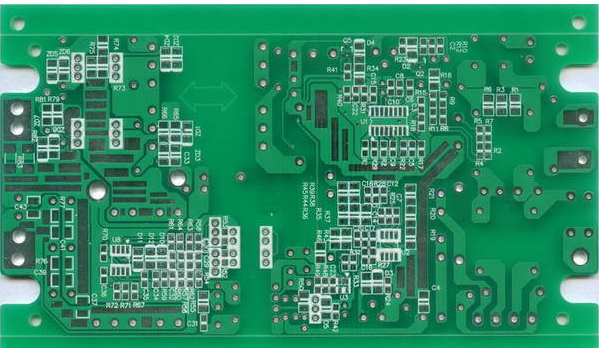

1. The printed circuit board is mainly composed of pads, vias, mounting holes, wires, components, connectors, filling, electrical boundaries, etc. The main functions of each component are as follows:

Circuit board production

Pad: A metal hole used to solder the pins of components.

Via: A metal hole used to connect the pins of components between layers.

Mounting hole: used to fix the printed circuit board.

Wire: The copper film of the electrical network used to connect the pins of the components.

Connectors: components used to connect between circuit boards.

Filling: Copper coating for the ground wire network, which can effectively reduce the impedance.

Electrical boundary: used to determine the size of the circuit board, all components on the circuit board cannot exceed the boundary.

2. The common layer structures of printed circuit boards include single layer PCB, Double Layer PCB and Multi ayer PCB. A brief description of these three layer structures is as follows:

1) Single-layer board: a circuit board with copper on one side and no copper on the other side. Usually components are placed on the side without copper, and the side with copper is mainly used for wiring and soldering.

(2) Double-layer board: a circuit board with copper on both sides, usually called the top layer on one side and the bottom layer on the other side. Generally, the top layer is used as the surface for placing components, and the bottom layer is used as the welding surface for components.

(3 Multilayer board: A circuit board that contains multiple working layers. In addition to the top and bottom layers, it also contains several intermediate layers. Usually the intermediate layers can be used as wire layers, signal layers, power layers, ground layers, etc. Layers and layers They are insulated from each other, and the layer-to-layer connection is usually achieved through vias.

Second, how to distinguish the quality of the PCB circuit board?

With the rapid development of the mobile phone, electronics, and communication industries, the PCB circuit board industry has continued to grow and grow rapidly, and at the same time, it has also prompted people to have higher and higher requirements for the number of layers, weight, precision, materials, colors, and reliability of the PCB.

However, due to the fierce market price competition, the cost of PCB board materials is also on a rising trend, and more and more manufacturers are monopolizing the market with low prices in order to enhance their core competitiveness. However, behind these ultra-low prices, it is obtained by reducing material costs and process manufacturing costs, which makes the PCB prone to cracks (cracks), scratches, (or scratches), and its precision, performance and other comprehensive factors do not meet the standards. Will seriously affect the solderability and reliability of the product and so on.

Faced with the various PCB circuit boards on the market, distinguishing the quality of PCB circuit boards can start from two aspects:

Circuit board production

One method is to distinguish and judge from the appearance, and the other is to judge from the quality specification requirements of the PCB board itself.

How to judge the quality of PCB circuit board:

First, the circuit board production distinguishes the quality of the circuit board from the appearance

Under normal circumstances, the appearance of the PCB circuit board can be analyzed and judged through three aspects:

1. Standard rules for size and thickness

The thickness of the circuit board is different from that of the standard circuit board. Customers can measure and check the thickness and specifications of their own products.

2. Light and color

The external circuit board is covered with ink, and the circuit board can play the role of insulation. If the color of the board is not bright, and there is less ink, the insulation board itself is not good.

3. Appearance of the weld

The circuit board has many parts. If the welding is not good, the parts are easy to fall off the circuit board, which seriously affects the welding quality of the circuit board. The appearance is good. It is carefully identified and the interface is strong.