First, in order to improve the qualified rate of products

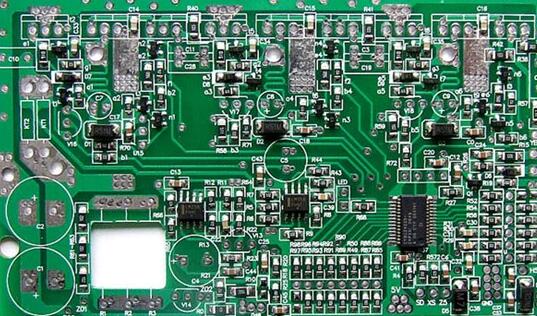

With the improvement of the qualified rate of the product, the through-pass rate of the product will be greatly improved. PCB Assembly testing is a link in the whole production process of PCBA processing, and is an important means to control product quality.

Second, to get a better user experience

If conditions permit, each product needs basic tests, such as test ICT, FCT test, some tests, such as fatigue test, pressure test in harsh environment, aging test, sampling can only detect the product, our heart will have a bottom, only stand the test of the product, the user will like. If problems are found in the testing process, we can also make timely corrections and adjustments to make the whole product more complete and avoid serious consequences after the product is put on the market.

Three, PCBA circuit board inspection conditions

1. In order to prevent the parts from being contaminated, you must choose EOS/ESD gloves or finger covers and wear an electrostatic ring. The light source is white or fluorescent. The light intensity must be at least 100 lux and can be clearly analyzed within 10 seconds.

2. Inspection method: Place the product about 40 cm away from your eyes, about 45 degrees up and down, and check with visual or triple magnifying glass.

3. inspection standards :(according to QS9000? Sampling sampling = 0 AQL = 0.4% level; As a special customer requirement, determined by customer acceptance criteria)

4. Sampling scheme: Mil-STD-105E Class ⅱ standard single sampling

5. determine the test criteria: serious defects (CR) AQL 0%

6. Main disadvantage (MA) AQL 0.4%

7. A minor defect (MI) AQL 0.65%

Four, PCBA board inspection standard

1. Serious defect (represented by CR) : any defect that can cause injury to people or machines or endanger life safety, such as non-compliance with safety regulations/burning of machines/electric shock.

2. Major defects (expressed by MA) : defects that may cause damage, abnormal function or affect the service life of products due to material reasons.

3. Minor defects (expressed by MI) : it does not affect the function and service life of the product, the appearance is defective, and the mechanism assembly has slight defects or differences.