PEST analysis

Policy environment analysis (P)

"Twelfth Five-Year Plan"

In order to further implement the "Outline of the National Medium and Long-term Science and Technology Development Plan (2006-2020)" and the "National "Twelfth Five-Year" Science and Technology Development Plan", on March 27, 2012, the Ministry of Science and Technology of the People's Republic of China Kefaji [2012] No. 193 issued the "Twelfth Five-Year Plan for Intelligent Manufacturing Technology Development". The "Plan" pointed out that intelligent manufacturing technology is the inevitable trend of the future development of advanced manufacturing technology and the inevitable demand for the development of the manufacturing industry. It is an important guarantee for seizing the commanding heights of industrial development and realizing China's transformation from a large manufacturing country to a powerful one.

Among them, the automated production line is one of the focuses of intelligent technology, equipment and research and development of the manufacturing process. The multi-track PCBA fully automatic online test platform developed by PCBA is an important part of the automated production line.

Economic environment analysis (E)

Scale analysis of automated testing industry

According to relevant survey reports, the output of China's automated production line industry reached 8,780 in 2014. In 2014, the total demand of China's automated production line industry reached 17,500. At present, the demand for automated production lines in China is mainly distributed in industries such as mobile phones, automobiles, and home appliances. Automated testing is an indispensable and important link in an automated production line.

Generally, there are 2-8 automated testing stations in an automated production line. Therefore, according to a fully automatic production line equipped with 2 automatic test stations, it is estimated that the potential market capacity of the multi-track PCBA fully automatic online test platform is at least 35,000 units, including the related output value of about 7 billion yuan, which does not include the use The multi-track PCBA automatic online test platform forms an independent test station.

Social environment analysis (S)

With the continuous development of science and technology, intelligent manufacturing and production automation have become common demands of the market. As an indispensable part of production automation, automated testing ushered in a golden period of development. At the same time, with the decline in the working population and the rise in the aging population, the supply and demand relationship of labor will also undergo corresponding changes. Many companies will face the problem of rising labor costs. Industrial automation will naturally become the general trend, and it will be embraced in the next few years. Come to the golden development period of the industry.

With the development of electronic product manufacturing and the continuous increase of labor costs, manufacturing companies are more and more willing and demanding for automation transformation, and the cost of re-introducing a new fully automatic test production line is high, so low cost and high efficiency are urgently needed. Transformation of existing production lines.

The fully automatic PCBA In Line online test platform has a high product starting point and advanced technology, which improves the industrial level, extends the industrial chain, promotes the upgrading of the traditional PCBA production industry, and accelerates the automation process. The research and development and production technology of the fully automatic PCBA In Line online test platform is a domestic initiative and tends to be a domestic leader, filling the gap in the technical solution for domestic automated testing and transformation. The fully automated PCBA In Line online test platform developed has improved PCBA production The degree of automation, low-cost and rapid transformation of existing traditional production lines, effectively improve production efficiency and reduce labor. Brings opportunities for the transformation of the traditional PCBA manufacturing industry. The research and production of this project will not only bring new profit growth points for enterprises, but also promote the development of related industries and enhance the quality and market competitiveness of related products.

Technical environment analysis (T)

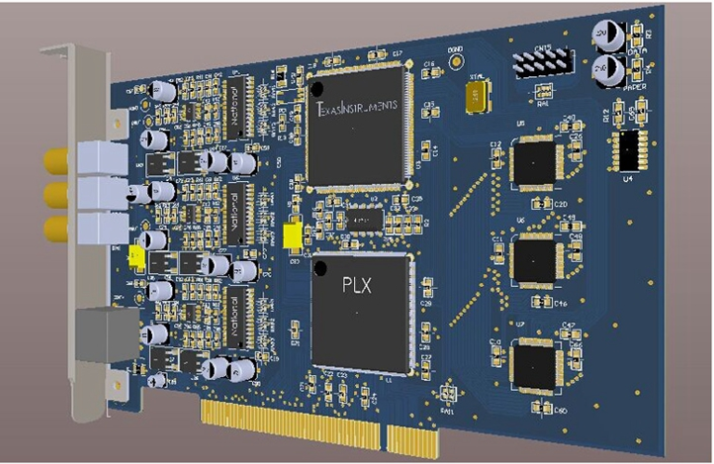

A printed circuit board (PCB) is a support for circuit components in electronic products and provides electrical connections between circuit components and components. The empty PCB board is assembled through surface mount technology (SMT) top parts and in-line component insertion, and the PCB that has been soldered and assembled with electronic components is a printed circuit board assembly (PCBA) board. With the rapid development of surface mount technology, higher requirements are placed on electronic assembly and test technology. At present, the commonly used testing techniques used in the field of electronic assembly testing include manual visual inspection (MVI), online testing (ICT), functional testing (FT), automated testing equipment (ATE), etc.

Most of the existing production line test stations use manual picking and placing of boards for testing. Each test station or each test equipment must be equipped with a corresponding operator. The degree of automation is not high, the test speed is slow, and the labor cost is high. Reduce the overall production efficiency, resulting in an increase in production costs. However, it is expensive to purchase automatic test equipment at home and abroad, and the non-automatic test equipment purchased by most companies has not yet reached the phase-out stage.

At present, fully automatic test production lines in the PCBA market are usually newly designed according to customer needs. Therefore, most traditional production lines need to add automatic test functions, and the entire production line must be redesigned and replaced. Or purchase brand new automated test equipment, and the current fully automated test equipment is based on the automation of its own equipment (that is, the focus is on the test function), which has the disadvantage of not being versatile, and there are not many products to choose from. This type of equipment faces four problems. One is the increase in procurement costs; the other is that the existing test equipment needs to be eliminated; the third is that the test fixtures used by different brands of equipment are not universal, resulting in an increase in subsequent use costs; the fourth is the use of new equipment There is a process of training and proficiency.