The pad falls off when the circuit board is soldered

In the process of using the circuit board, the pads often fall off, especially when the circuit board is reworked. When using an electric soldering iron, the pads are very easy to fall off. Then why?

1. Board quality problems. Because the adhesion of the resin glue between the copper foil of the copper clad sheet and the epoxy resin is poor, even if the copper foil of the circuit board with a large area of copper foil is slightly heated or under mechanical external force, it is very easy to interact with the epoxy The separation of the resin causes problems such as peeling of the pad and peeling of the copper foil.

2. The influence of circuit board storage conditions. Affected by the weather or stored in a damp place for a long time, the circuit board absorbs moisture too high. In order to achieve the ideal welding effect, the patch needs to compensate for the heat taken away due to the volatilization of moisture, the welding temperature and Time needs to be extended. Such soldering conditions can easily lead to delamination of the copper foil and epoxy resin of the circuit board.

3. Electric soldering iron soldering problem, the adhesion of ordinary circuit boards can meet ordinary soldering, and there will be no pads falling off, but electronic products are usually repaired. Rework is usually done by soldering with an electric soldering iron, because the electric soldering iron Local high temperature can often reach a temperature of 300-400 degrees, which also causes the local instantaneous temperature of the pad to be too high, and the resin glue under the copper foil of the pad falls off due to the high temperature, and the pad falls off. When the soldering iron is disassembled, it is very easy to attach the physical force of the soldering iron tip to the pad, which is also a factor that causes the pad to fall off.

As for the pads are easy to fall off under the conditions of use, the following measures are generally taken to increase the number of soldering resistance of the circuit board pads as much as possible to meet the needs of customers.

1: The copper clad laminate is made of a base material produced by a genuine and quality-guaranteed manufacturer. The glass fiber cloth material selection and pressing process of ordinary genuine copper clad laminates can ensure that the solder resistance of the manufactured circuit boards meets the requirements of customers.

2: The circuit board is vacuum packed before leaving the factory, and desiccant is placed to keep the circuit board in a dry condition. Create conditions to reduce false welding and improve weldability.

3: Regarding the thermal impact of the soldering iron on the pad during rework, it is best to increase the thickness of the copper foil of the pad through electroplating, so that when the soldering iron heats the pad, the thermal conductivity of the pad with thick copper foil becomes significantly stronger, Which effectively reduces the local high temperature of the pad, and the fast heat conduction makes the pad easier to disassemble, and realizes the solder resistance of the pad.

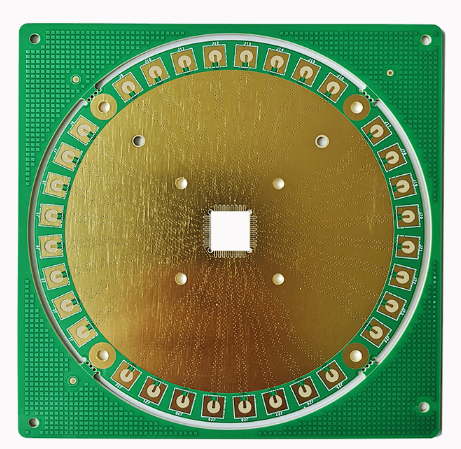

ipcb is a high-precision, high-quality PCB manufacturer, such as: isola 370hr PCB, high-frequency PCB, high-speed PCB, ic substrate, ic test board, impedance PCB, HDI PCB, Rigid-Flex PCB, buried blind PCB, advanced PCB, microwave PCB, telfon PCB and other ipcb are good at PCB manufacturing.