Under the fierce market competition in the PCB circuit board industry today, production technology is one of the main ways to create fast delivery, reduce costs, and improve quality. Here is an explanation of the two PCB board production processes that often appear, but many PCB manufacturers do not know How to improve the problem.

1. In the production process of the circuit board, the surface of the photosensitive solder mask black and white oil often appears after development. There is a layer of black and white dust on the surface, which can be wiped off with dust-free paper.

Similar problems have been seen in no less than ten circuit board factories. Everyone who asked for advice said that it was baked to death during pre-bake, which caused unclean development. They generally used the method of shortening the baking time. To solve this problem, the result was counterproductive. When asked about the conditions of their baking sheets, they were mostly at 75 degree Celsius*25-35 minutes, printing on both sides at the same time.

However, the supervisor of the welding room (dry area) of the PCB board factory should be able to solve this problem by himself, and the simplest problem is often worsened by the unskilled people. I have seen a PCB board manufacturer’s welding room supervisor appear After such a problem, the griller was ordered to bake the photosensitive white oil board at 75 degree Celsius*20 minutes, and the exposure ruler achieved 8 levels of residue. The result was a white fog on the whole board after the development. However, the supervisor was confused and gave the company. Bring great losses.

The above problem is actually very simple. The main reason is that the photosensitive black and white oil baking time is insufficient, and the exposure energy is too low, causing the photosensitive black and white oil bottom layer to not fully achieve the effect of heat and light dual curing, so the surface layer will fall off after development The black and white oil is in powder form, which will appear on the surface after being dried by the developing machine, which can be wiped off with dust-free paper.

To solve this problem, we only need to pre-bake for a long time. Generally, the condition of pre-bake photosensitive black and white oil is 75 degree Celsius+5 degree Celsius*40-50 minutes, depending on the thickness of the board. Use 21-frame exposure to achieve 11-level residual and 12-level clean.

If you encounter similar problems, please refer to the above process, I believe it will achieve the desired effect.

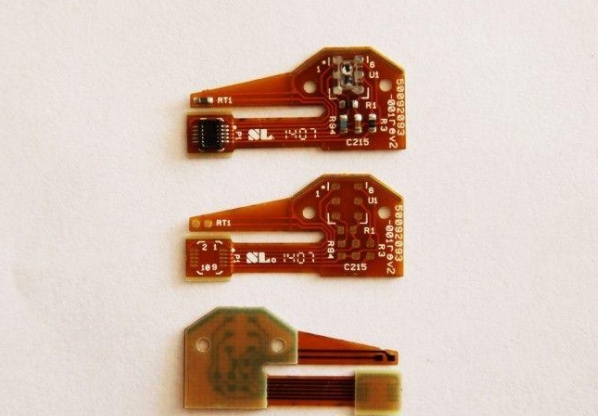

2. When printing solder mask oil, it is often found that there is oil in the socket and the development is not clean.

Similar problems have also been encountered by several PCB board factories. The main reason is that there is oil in the hole after development and it is not clean, and it is used for back flushing, but it is still not clean. Finally, the caustic soda is used for backwashing, but the result is still in the hole. The oil still can't be washed off, and the residual oil in the hole can't be removed at the end, resulting in scrap.

Such a problem will not be scrapped if it is properly handled. The main reason for scrapping is that the silk screen is not well controlled during printing, which makes the oil into the hole too serious. During pre-baking, the oil in the hole is too thick, can it not be displayed after the re-developing of the oil in the hole? We can do a test and use a small blade to pick out the oil in the hole to see that it is sure that the oil in the hole is thin Yes, if the thin oil is re-developed, the oleoresin bond on the wall of the hole cannot be washed away.

Why can't it be washed off again with caustic soda? When the ink itself is not pre-baked, the ink that has been soaked in Na2CO3 and soaked in caustic soda will be killed by the attack of two chemical yao waters. Immerse the color of the ink into the base material of the hole wall, just like the common ink in our lives puts on the clothes, soaked with yarn, it can not be washed off, the result is that there is a layer of green oil in the hole at the end. Cause scrap.