Horizontal plating technology is a method of plating printed circuit boards parallel to the level of the plating solution. This method allows for uniform and efficient current flow during the plating process, which improves the quality of the plating. This plating method is mainly used for high aspect ratio through-hole plating to accommodate the complex needs of PCB manufacturing.

Horizontal plating is based on the accelerated convection of the plating solution, which creates eddy currents and effectively reduces the thickness of the diffusion layer to approximately 10 microns. This characteristic enables horizontal plating systems to perform plating at current densities of up to 8 A/dm², ensuring excellent plating results. In such systems, the circuit board acts as the cathode and efficient deposition of the plated layer is achieved through the interaction of the plating solution and the current.

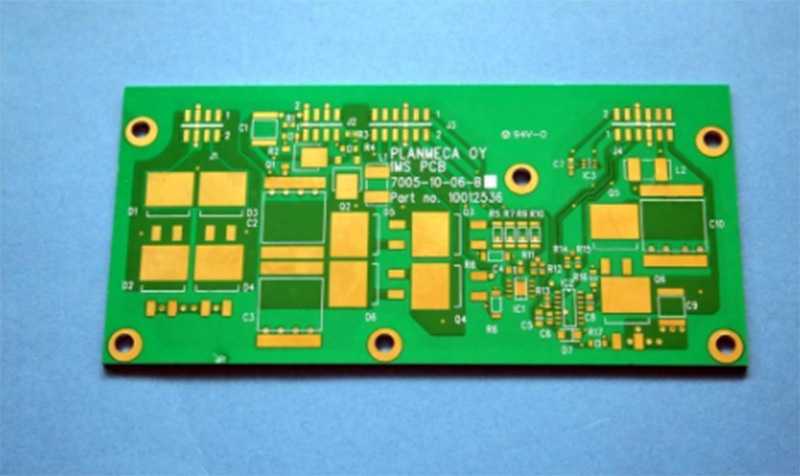

Horizontal plating technology offers several advantages, including fast plating speeds, uniform plating layers, and the ability to plate complex shaped components. This has led to a wide range of potential applications in a variety of fields, including consumer electronics, medical devices and industrial applications. For example, in high-performance consumer electronics, horizontal plating can effectively improve the electrical performance and reliability of circuit boards.

According to the characteristics of horizontal electroplating,it is an electroplating method in which the printed circuit board is placed from a vertical type to a parallel plating liquid surface. At this time,the circuit board is the cathode,and some horizontal electroplating systems use conductive clamps and conductive rollers for current supply.From the convenience of the operating system, it is common to use the roller conductive supply method. The conductive roller in the horizontal electroplating system not only serves as the cathode,but also has the function of conveying the pcb board. Each conductive roller is equipped with a spring device, the purpose of which can be adapted to the electroplating needs of printed circuit boards of different thicknesses (0.10-5.00mm).However,during electroplating, all parts in contact with the plating solution may be plated with a copper layer, and the system will not work for a long time. Therefore, most of the currently manufactured horizontal electroplating systems design the cathodes to be switchable to anodes,and then use a set of auxiliary cathodes to electrolytically dissolve the copper on the plated rollers. For the sake of maintenance or replacement, the new electroplating design also considers the parts that are prone to wear and tear to facilitate removal or replacement.The anode adopts an array of adjustable size insoluble titanium baskets, which are placed on the upper and lower positions of the printed circuit board,and are equipped with a spherical shape of 25mm in diameter and a phosphorus content of 0.004-0.006% soluble copper. The distance between the cathode and the anode It is 40mm.

The flow of the plating solution is a system composed of pumps and nozzles,which makes the plating solution flow alternately and rapidly in the closed plating tank back and forth,up and down,and can ensure the uniformity of the plating solution flow. The plating solution is sprayed vertically to the printed circuit board,forming a wall jet vortex on the surface of the printed circuit board.The ultimate goal is to achieve rapid flow of plating solution on both sides of the printed circuit board and through holes to form eddy currents.

In addition, a filter system is installed in the tank, and the filter mesh used is 1.2 microns to filter out the particulate impurities generated during the electroplating process to ensure that the plating solution is clean and pollution-free.

Advantages and Disadvantages of Horizontal Plating vs. Conventional Plating

1. Advantages

Production efficiency

Horizontal plating has a faster plating speed,which makes the production process more efficient. Compared to conventional vertical plating, horizontal plating is able to deposit the plated layer in a shorter period of time, thus increasing the overall productivity.

Plating Uniformity

Horizontal plating provides a more uniform layer thickness and reduces unevenness.This uniformity ensures board performance and reliability,especially for high-density, high-precision multilayer printed circuit boards.

Adaptability

The technology is adaptable to complex shaped assemblies and is especially superior in the manufacture of through-holes with high aspect ratios.The flexibility of horizontal plating makes it more suitable for the diverse needs of modern electronic products.

2. Disadvantages

Cost

Despite the efficiency and quality advantages of horizontal plating technology,equipment investment and maintenance costs are relatively high.The initial investment required for more automated systems may increase the total cost.

Technical Complexity

Horizontal plating is a relatively complex process that requires specific types of conductive brushes for effective contact.This technical complexity may result in lower yields and reduced reliability.

Equipment Requirements

Horizontal plating has more stringent equipment requirements,requiring highly accurate and stable production facilities.This may limit the application capabilities of some smaller companies and raise the bar for the industry.

When PCB manufacturing a horizontal electroplating system,the convenience of operation and the automatic control of process parameters must also be considered. Because in actual electroplating,with the size of the printed circuit board,the size of the through-hole aperture and the required copper thickness,the transmission speed,the distance between the printed circuit boards,the size of the pump horsepower,and the nozzle.The setting of the process parameters such as the direction of the current density and the level of the current density requires actual testing,adjustment and control to obtain the copper layer thickness that meets the technical requirements.It must be controlled by a computer.In order to improve the PCB production efficiency and the consistency and reliability of the quality of high-end products,the through-hole processing (including plated holes) of the printed circuit board is formed according to the process procedures to form a complete horizontal electroplating system to meet the development and launch of new products. Needs.