Disassemble the components on the single-sided printed PCB: toothbrush method, screen method, needle method, tin suction device, pneumatic suction gun, etc. can be used. Table 1 compares these methods in detail.

Most of the simple methods for disassembling electronic components (including advanced foreign pneumatic sniffer) are only suitable for single panel, and the effect is not good for double panel and multi panel.

2. Disassemble the components on the double-sided printed PCB board: single-side integral heating method, needle tube hollowing method, tin flow soldering machine can be used. The single-link integral heating method requires special heating tools, which is inconvenient for general use. Needle tube hollowing method: first cut off the pins of the components that need to be disassembled, and remove the components. At this time, the pins of the components that have been cut off are left on the printed PCB board, and then each pin is removed with a soldering iron. Melt the tin on the upper part, use tweezers to take it out until all the pins are taken out, and then use a medical needle that matches the inner diameter of the pad hole to hollow it out. Although this method requires several more processes, it is not suitable for printed PCB boards. There is no impact, it is convenient to obtain materials and easy to operate, and it is extremely easy to realize. After many years of practice, I think it is an ideal method.

3. Disassemble the components on the multi-sided printed PCB board: If the above methods (except tin flow soldering machine) are used, it is either difficult to disassemble, or it is easy to cause connection failures between layers. Generally, the soldering pin method is used to cut the component from the root of the component pin, leave its pin on the printed PCB board, and then solder the pin of the new device on the pin left on the printed PCB board. But it is not easy to weld multi-leg integrated blocks. The tin flow soldering machine (also known as the secondary soldering machine) can solve this problem and is the most advanced tool for disassembling the integrated blocks on the double and multilayer printed PCB boards. However, the cost is relatively high, requiring an investment of several thousand yuan. The tin flow soldering machine is actually a special small wave soldering machine. It uses a tin flow pump to extract fresh and unoxidized molten tin from the tin pot and gush out through the optional different specifications of spray nozzles to form a The local small wave peaks act on the bottom of the printed PCB. The pins and solder holes of the removed components on the printed circuit board will melt immediately within 1 to 2 seconds. At this time, it can be pulled out lightly. Then use compressed air to blow through the solder hole of the component, re-insert the new component, and then solder the finished product on the wave crest of the spray nozzle.

Of course, in addition to the above, there are other methods (for example: copper wire method, alcohol lamp method, etc.), but because of its lack of outstanding features, it is similar to the method described above, so I won't talk about it here.

In our daily life, most of the household appliances we use are single-panel. Although various simple methods have their own characteristics, it is recommended to use a solder suction device. For double and multi-panel, the simple method mentioned above can be used, and the economy permits, it is better to use a tin flow soldering machine.

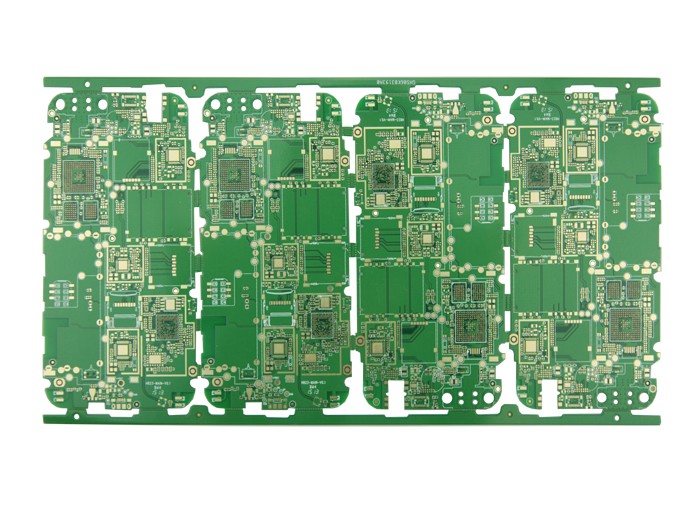

The above is the disassembly method of the components on the printed PCB. The ipcb company also provides PCB manufacturers, PCB board design technology, etc.