What is the difference between SMT and THT on PCB circuit board?

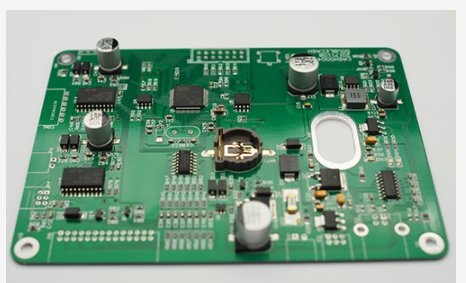

SMD assembly(SMT and THT) refers to the placement of chip-shaped components or miniaturized components suitable for surface assembly on the surface of the printed circuit board according to the requirements of the circuit, and soldering by reflow soldering or wave soldering The process is assembled; and then used in the production of the finished product. So, what is the difference between PCB circuit board SMT and THT?

SMT is a surface mount technology, and THT is a traditional through-hole insertion technology. From the perspective of assembly process technology, the fundamental difference between SMT and THT is "sticking" and "inserting." On the THT circuit board, the components and solder joints are located on both sides of the board; while on the SMT circuit board, the solder joints and components are on the same side of the board. Therefore, on the SMT circuit board, the through holes are only used to connect the wires on both sides of the circuit board, the number of holes is much smaller, and the diameter of the holes is much smaller. In this way, the assembly density of the circuit board can be greatly improved.

1. The advantages of SMT packaging:

1. Effectively save PCB area;

2. Provide better electrical performance;

3. Protect the interior of the components from humidity and other environmental influences;

4. Provide good communication links;

5. Help heat dissipation and provide convenience for transmission and testing.

2. Compared with THT, SMT has the following advantages:

1. Realize miniaturization. The geometric size and volume of SMT electronic components are much smaller than those of through-hole plug-in components, which can generally be reduced by 60% to 70% and weight by 60% to 90%.

2. The signal transmission speed is high. SMT has a compact structure and high assembly density, which can reach 5.5-20 solder joints/cm; due to the short connection and low delay, it can realize high-speed signal transmission; at the same time, it is more resistant to vibration and shock. This is of great significance to the ultra-high-speed operation of electronic equipment.

3. Good high frequency characteristics. Since the components have no leads or short leads, the distribution parameters of the circuit are naturally reduced and radio frequency interference is reduced.

4. It is conducive to automated production and improves the yield and production efficiency.

5. The material cost is low. The packaging cost of most SMT components is already lower than that of iFHT components of the same type and function; consequently, the selling price of SMT components is lower than that of THT components.

6. SMT technology simplifies the production process of the complete product, reduces production costs, and improves production efficiency. The processing cost of the functional circuit is lower than that of the through-hole insertion method, which generally reduces the total production cost by 30% to 50%.

The above is the difference between PCB circuit board SMT and THT shared by professional PCB manufacturers. I believe you must have some understanding of this, right?