The original name of the circuit board comes from the English Printed Circuit Board,while the Chinese is translated as "Printed Circuit Board".Some people also call it PWB (Printed Wiring Board). As the name implies, this product is a circuit product made by printing technology. He replaced the copper wire distribution method for electrical products before the 1940s, which accelerated mass production replication, reduced product volume, increased convenience, and lowered unit prices.

The most advanced circuit board is to melt the metal to cover the surface of the insulating board to make the required circuit.After 1936, the production method has shifted to selecting areas of insulating substrates covered with metal using corrosion-resistant inks, and removing unnecessary areas by etching. This method is called (Subtractive Method).

The evolution of PCB board technology: From the arts and crafts to printing technology to the construction of electronic circuits, a series of transformations that began before 1913, when Berry first applied the subtractive process to the production of electric heaters and described “heated” strips, which can be seen as a prototype for flexible circuit boards. In fact, Hanson had begun exploring different ways to compactly arrange a large number of conductors to solve the problem of cluttered telephone switchboard wiring long before Berry, in 1903. All of these designs used wires and a variety of insulating materials such as paper, gutta-percha, and cellulose. Significantly, Hanson mentions in his patent that he fabricates conductors by “electrodeposition or mechanical deposition, such as drawing lines of powdered metal directly on the insulation in a suitable medium.” Looking back at this patent, it is easy to see the beginnings of many modern circuit concepts, including double-sided through-hole circuits, multilayer circuits, high-density circuits, and another additive process that differs from King's method of circuit board production.

In 1915, Chisholm worked to improve the manufacturing process for lithographic printing plates by using electrodeposition of copper followed by nickel deposition to obtain a uniform, more flexible and resilient surface.To provide a sufficient surface for metal deposition, he used volatile solvents, fine metal powders, and porous substrates, which may be regarded as precursors to conductive pastes and inks.

Next, Charles Ducas became an important inventor. His 1925 patent is cited in at least five other patents (including Eisler,1948; McLarn,1947; Nieter, 1955a, b; Rubin, 1948), all of which are based on different variations of Ducas's method Ducas worked to find alternative methods of producing conductors that avoided the need to wind single-stranded wires. To this end, he used a variety of methods to produce metallization patterns on insulating materials, and subsequently plated panels containing metallized circuits to deposit the desired amount of metal. The panels are fabricated in a variety of ways, including but not limited to:

Exposing the metal portion of the desired design using a lathe on a substrate, which consists of a conductive material coated with a non-conductive layer.

Transferring the image to a blank panel using a conductive paste.

Printing the image in a low melting point substance (e.g. wax) and then coating it with a conductive material.

Conductive paste and arbitrary printing techniques are used to create the desired image.

In addition, Charles Ducas mentions conductors that can be made on both sides of an insulating substrate and describes a method of extending the conductors of each layer through holes to the other side to make interlayer connections, which hints at the concept of multilayer circuits, but the inventor does not elaborate further on this.

After 1960, the product market of record players, tape recorders, and video recorders successively adopted double-sided through-hole circuit board manufacturing technology, so the heat-resistant and stable size epoxy resin substrate was widely used, and it is still the main resin for circuit board production.

With the evolution of semiconductor technology, electronic products are moving towards higher density structures. Electronic assembly is a one-to-one combination structure. When the density of electronic components increases, of course, the carrier circuit board of the component will also need to increase the connection density, which has gradually formed the design trend of today's high-density circuit board.

Although the concept of build-up circuit boards has appeared in products successively since 1967,it was not until IBM released SLC technology in 1990 that microvia technology gradually became mature and practical. Prior to this, if the full-board through holes of the circuit board were not used, the designer would use multiple pressing methods to obtain a higher wiring density. Due to the rapid advancement of materials, photosensitive and non-photosensitive insulating materials have been listed one after another, and the micro-hole Technology has gradually become the main design structure of high-density circuit boards and appears in many mobile electronic products.

In the connection between circuit layers, in addition to electroplating, the use of conductive paste technology for connectors has also appeared one after another. The more well-known ones are the ALIVH method published by Panasonic and the B2it method published by Toshiba. These technologies are applied to circuit boards. Into the era of high density (High Density Interconnection-HDI).

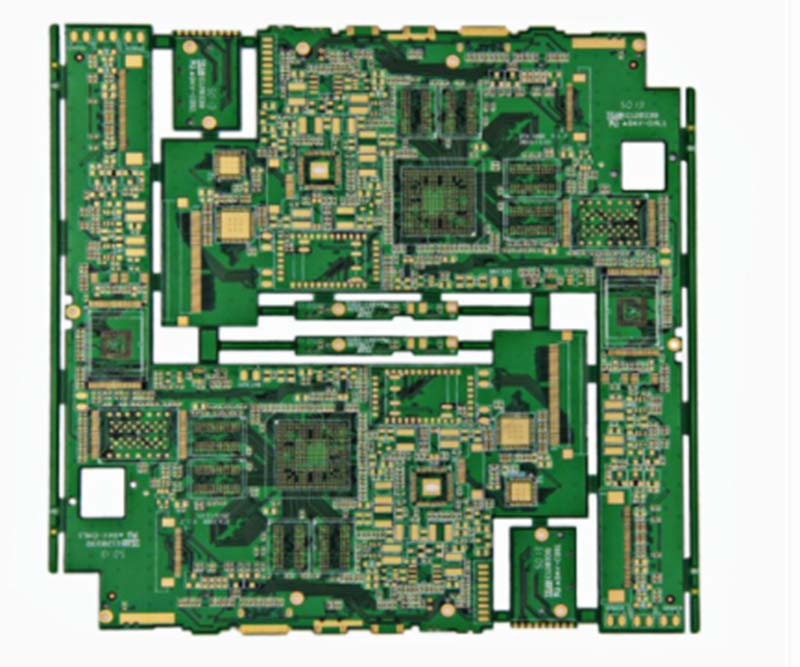

Printed circuit board (PCB) as a bridge between electronic components and relay transmission medium, while carrying the role of support, known as “the cornerstone of electronic products”.PCB manufacturing process quality is not only directly related to the reliability of electronic products, but also profoundly affects the accuracy of signal transmission between different chips, therefore, the level of development of PCB industry to a certain extent maps the technical strength of a country or region information technology (IT) industry.PCB technology progress is closely linked with the development of integrated circuit industry, the rapid progress of semiconductor technology to promote the PCB industry technology strength. The level of development of the PCB industry maps out the technical strength of a country or region's information technology (IT) industry to a certain extent.The progress of PCB technology is closely linked to the development of the integrated circuit industry, and the rapid advancement of semiconductor technology has driven the continuous evolution and increasing maturity of PCB industry technology. Since 1936, PCB was first used in radio, nearly a hundred years, PCB technology has experienced from single-panel, dual-panel to multi-panel, from the insertion technology to surface mount technology (SMT), and then to the ball grid array package (BGA) of the great change. In the field of PCB processing, graphic production, laser drilling, surface coating and testing processes have made new progress, blind holes, buried holes and layer method and other technologies are increasingly widely used, while high-density and high-performance has become the main trend in the evolution of PCB technology.

The upstream link of PCB board industry chain covers all kinds of raw materials, such as copper-clad laminate (CCL), semi-cured sheet, copper foil, copper ball, gold salt, dry film and ink, etc.; the midstream is the production of PCB manufacturing; downstream is widely used in communications, consumer electronics, automotive electronics, industrial control, medical, aerospace, national defense, and semiconductor packaging and other fields. In the operating cost of PCB, the cost of raw materials accounted for a high proportion, usually about 60%, of which the cost of CCL accounted for the largest proportion of 30%, the importance of which is self-evident, followed closely by copper foil (9%), copper ball (6%) and ink (3%) and so on. As the core material for PCB manufacturing, the production of CCL mainly relies on three major raw materials: copper foil, resin and fiberglass cloth, which are respectively responsible for the PCB's conductive, insulating and supporting functions, of which copper foil accounts for 42%, resin accounts for 26%, and fiberglass cloth accounts for 19%.