Model : Power Module PWB

Material : High TG FR4

Layer : 12Layers

Color : Green/White

Finished Thickness : 1.0mm

Copper Thickness : 2-3OZ

Surface Treatment : Immersion Gold

Min Trace : 8mil(0.2mm)

Min Space : 8mil(0.4mm)

Application : Power Module PWB

The power module PWB is a printed circuit board that can be directly mounted on the power supply of the PWB. Its characteristic is that it can be an application-specific integrated circuit (ASIC), digital signal processor (DSP), microprocessor, memory, and field programmable gate. Array (FPGA) and other digital or analog loads provide power. Generally speaking, this type of module is called a load (POL) power supply system or a point-of-use power supply system (PUPS). Due to the many advantages of the modular structure, the modular power supply is widely used in switching equipment, access equipment, mobile communications, microwave communications, optical transmission, routers and other communications fields, as well as automotive electronics, aerospace, and so on.

According to the application fields of modern power electronics, we divide the power module as follows:

Green power module

The rapid development of computer technology has not only led mankind into the information society, but also promoted the rapid development of power module technology. In the 1980s, computers fully adopted switching power supply and took the lead in completing the replacement of computer power supply. Then switching power supply technology has entered the field of electronic and electrical equipment.

With the development of computer technology, green computer and green power module are proposed. Green computer generally refers to personal computers and related products that are harmless to the environment. Green power supply refers to the high-efficiency and power-saving power supply related to green computers. According to the "Energy Star" of the U.S. Environmental Protection Agency on June 17, 1992 "The plan stipulates that if the power consumption of desktop personal computers or related peripherals is less than 30 watts during sleep, it meets the requirements of green computers. Improving power efficiency is the fundamental way to reduce power consumption. For the 200 Watt switching power supply with 75% efficiency, the power supply itself consumes 50 watts of energy.

Switching power supply module

The rapid development of communication industry has greatly promoted the development of communication power supply. High frequency miniaturized switching power supply and its technology have become the mainstream of modern communication power supply system. In the field of communication, rectifier is usually called primary power supply, and DC-DC (DC / DC) is used The converter is called the secondary power supply. The primary power supply is used to convert the single-phase or three-phase AC power grid into a DC power supply with a nominal value of 48V. At present, among the primary power supplies used in program-controlled switches, the traditional phase controlled regulated power supply has been replaced by high-frequency switching power supply (also known as switching rectifier SMR) Through the high-frequency operation of MOSFET or IGBT, the switching frequency is generally controlled in the range of 50-100khz to achieve high efficiency and miniaturization. In recent years, the power capacity of switching rectifier has been expanding, and the single machine capacity has been expanded from 48V / 12.5A and 48V / 20a to 48V / 200A and 48V / 400A.

Switching Mode Power Supply

Due to the wide variety of integrated circuits used in communication equipment and different power supply voltages, high-frequency DC-DC isolation power module with high power density is used in communication power supply system to isolate the power supply module from the intermediate bus voltage (generally 48V DC) It can be converted into various DC voltages required, which can greatly reduce the loss, facilitate maintenance, and is very convenient for installation and increase. Generally, it can be directly installed on the standard control board. The requirement for the secondary power supply is high power density. Due to the continuous increase of communication capacity, the capacity of communication power supply will also increase.

Converter

DC / DC converter converts a fixed DC voltage into a variable DC voltage. This technology is widely used in the stepless speed change and control of trolleybus, subway train and electric vehicle. At the same time, the above control can achieve the performance of stable acceleration and fast response, and save electric energy. Replacing rheostat with DC chopper can save electric energy (20 ~ 30) %The DC chopper can not only regulate the voltage (switching power supply), but also effectively suppress the harmonic current noise at the power grid side.

The secondary power DC / DC converter of communication power supply has been commercialized. The module adopts high-frequency PWM technology. The switching frequency is about 500KHz and the power density is 5W ~ 20W / in3. With the development of large-scale integrated circuits, the power module is required to realize miniaturization. Therefore, it is necessary to continuously improve the switching frequency and adopt new circuit topology. At present, some companies have developed and produced zero current switch and zero power The secondary power supply module of voltage switching technology has greatly improved the power density.

UPS

Uninterruptible power supply (UPS) It is a highly reliable and high-performance power supply required for computers, communication systems and occasions that cannot be interrupted. The AC mains input is changed into DC through the rectifier, part of the energy is charged to the battery pack, and the other part of the energy is changed into AC through the inverter and sent to the load through the conversion switch. In order to still provide energy to the load in case of inverter failure, another standby power supply passes through Power transfer switch.

Modern UPS generally adopts pulse width modulation technology, power M0SFET, IGBT and other modern power electronic devices, so that the noise of power supply can be reduced and the efficiency and reliability can be improved. The introduction of microprocessor software and hardware technology can realize the intelligent management, remote maintenance and remote diagnosis of ups.

The maximum capacity of On-line UPS can reach 600KVA. Ultra small ups is also developing rapidly, and there are products of 0.5kva, LVA, 2KVA, 3KVA and other specifications.

Inverter power supply

Inverter power supply is mainly used for variable frequency speed regulation of AC motor. It plays an increasingly important role in the electrical transmission system and has achieved great energy-saving effect. The main circuit of inverter power supply adopts AC DC AC scheme. The power frequency power supply becomes a fixed DC voltage through rectifier, and then the PWM high-frequency converter composed of high-power transistor or IGBT reverses the DC voltage into DC voltage AC output with variable voltage and frequency. The power output waveform is similar to sine wave, which is used to drive AC asynchronous motor to realize stepless speed regulation.

A series of inverter power supply products below 400KVA have come out in the world. In the early 1980s, Toshiba Corporation of Japan first applied AC variable frequency speed regulation technology to air conditioners. By 1997, its share had reached more than 70% of Japan's household air conditioners. Variable frequency air conditioners have the advantages of comfort and energy saving. China began to study variable frequency air conditioners in the early 1990s and introduced production lines to produce variable frequency air conditioners in 1996 Frequency conversion air conditioner has gradually become a hot spot in the development and production of frequency conversion air conditioner. It is expected to reach a climax by about 2000. In addition to frequency conversion power supply, frequency conversion air conditioner also requires compressor motor suitable for frequency conversion speed regulation. Optimizing control strategy and selecting functional components are the further development direction of frequency conversion power supply of air conditioner.

Welder power module

High frequency inverter rectifier welding power supply is a new welding power supply with high performance, high efficiency and material saving, which represents the development direction of welding power supply. Due to the commercialization of IGBT large capacity module, this power supply has a broad application prospect.

Most inverter welding machine power supplies adopt ac-dc-ac-dc (ac-dc-ac-dc) conversion method. 50Hz AC is converted into DC through full bridge rectification, and the PWM high-frequency conversion part composed of IGBT reverses the DC into 20kHz high-frequency rectangular wave, which is coupled by high-frequency transformer, rectified and filtered to become stable DC, and the power supply arc is used.

Due to the poor working conditions of the welding machine power supply, which is frequently in the alternating change of short circuit, arc burning and open circuit, the working reliability of the high-frequency inverter rectifier welding machine power supply has become the most critical problem and the most concerned problem of users. Microprocessor is used as pulse width modulation (PWM) Through the extraction and analysis of multi parameters and multi information, the relevant controller can predict various working states of the system, and then adjust and process the system in advance, so as to solve the reliability of current high-power IGBT inverter power supply.

Foreign inverter welding machines can achieve rated welding current of 300A, load duration rate of 60%, full load voltage of 60 ~ 75V, current regulation range of 5 ~ 300A and weight of 29kg.

DC power module

High power switch type high voltage DC power supply is widely used in electrostatic dust removal, water quality improvement, medical X-ray machine, CT machine and other large equipment. The voltage is up to 50 ~ l59kv, the current is more than 0.5A, and the power is up to 100kW.

Since the 1970s, some Japanese companies began to use inverter technology to invert the mains power into an intermediate frequency of about 3kHz after rectification, and then boost the voltage. In the 1980s, high-frequency switching power supply technology developed rapidly. German Siemens used power transistors as the main switching elements to increase the switching frequency of the power supply to more than 20kHz. And the dry-type transformer technology was successfully applied to high-frequency and high-voltage The high-voltage transformer oil tank is cancelled to further reduce the volume of the transformer system.

Power module

Power module

The high-voltage DC power supply for electrostatic precipitator has been developed in China. The mains power is transformed into DC through rectification. The DC voltage is inverted into high-frequency voltage by using full bridge zero current switch series resonant inverter circuit, and then boosted by high-frequency transformer. Finally, it is rectified into DC high-voltage. Under the condition of resistance load, the output DC voltage reaches 55kV, the current reaches 15mA and the working frequency is 25.6khz.

wave filter

When the traditional AC-DC converter is put into operation, it will inject a large amount of harmonic current into the power grid, causing harmonic loss and interference. At the same time, there is also the phenomenon of deterioration of the power factor at the grid side of the device, that is, the so-called "power pollution". For example, when uncontrollable rectification and capacitive filtering are added, the third harmonic content at the grid side can reach (70 ~ 80)%, and the power factor at the grid side is only 0.5 ~ 0.6.

Active power filter is a new power electronic device that can dynamically suppress harmonics. It can overcome the shortcomings of traditional LC filter and is a promising means of harmonic suppression. The filter is composed of bridge switching power converter and specific control circuit. The difference from traditional switching power supply is: (1) not only feedback output voltage, but also feedback input average current; (2) The current loop reference signal is the product of the voltage loop error signal and the full wave rectified voltage sampling signal.

power supply system

The distributed power supply system uses low-power modules and large-scale control integrated circuits as basic components, and uses the latest theories and technical achievements to form a building block and intelligent high-power power supply, so as to closely combine strong current with weak current, reduce the development pressure of high-power components and high-power devices (centralized) and improve production efficiency.

In the early 1980s, the research on distributed high-frequency switching power supply system basically focused on the research of converter parallel technology. In the middle and late 1980s, with the rapid development of high-frequency power conversion technology, various converter topologies appeared one after another. Combined with large-scale integrated circuit and power component technology, the integration of small and medium-sized power devices became possible, which quickly promoted the development of power distribution Since the late 1980s, this direction has become a research hotspot in the international power electronics field. The number of papers is increasing year by year and the application field is expanding.

Distributed power supply has the advantages of energy saving, reliability, high efficiency, economy and convenient maintenance. It has been gradually adopted by mainframe computers, communication equipment, aerospace, industrial control and other systems. It is also a low-voltage power supply (3.3V) for ultra-high speed integrated circuits It also has broad application prospects in high-power occasions, such as electroplating, electrolytic power supply, electric locomotive traction power supply, medium frequency induction heating power supply, motor drive power supply and so on.

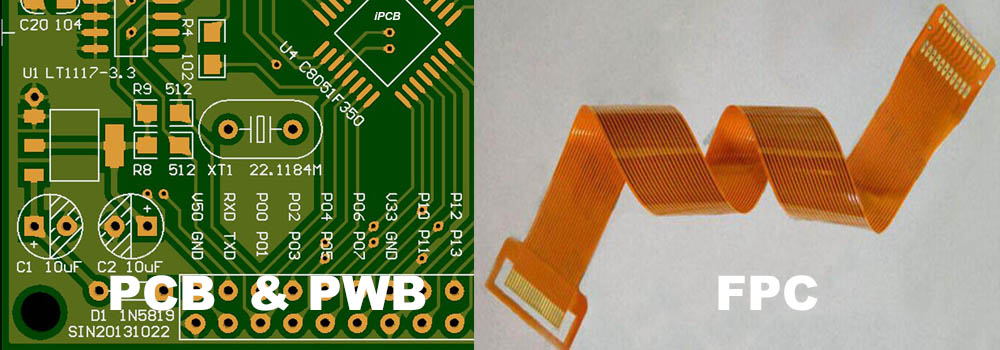

PCBvs PWB, PWB vs FPC

PCB vs PWB, PWB vs FPC

PCB: is the abbreviation of Printed circuit board, the official translation is printed circuit board or printed circuit board, or printed circuit board; including printed circuit graphics and printed components;

PWB: is the abbreviation of Printed wire board, the official translation is printed circuit board, which is the early name of the British, because at that time there were only circuit diagrams on the circuit board and no printed components, so it was a relatively primitive board;

FPC: is the abbreviation of Flexible printed board. Also known as soft board.

In fact, PWB and PCB are both PCBs. Today everyone calls it PCB, but it is rarely called PWB. PCB are divided into rigid PCB and flexible PCB. At present, the PCB industry is used to call rigid PCB and flexible PCB as FPC.

Model : Power Module PWB

Material : High TG FR4

Layer : 12Layers

Color : Green/White

Finished Thickness : 1.0mm

Copper Thickness : 2-3OZ

Surface Treatment : Immersion Gold

Min Trace : 8mil(0.2mm)

Min Space : 8mil(0.4mm)

Application : Power Module PWB

For PCB technical problems, iPCB knowledgeable support team is here to help you with every step. You can also request PCB quotation here. Please contact E-mail sales@ipcb.com

We will respond very quickly.