The low hygroscopicity of RT/duroid 6010LM microwave PCB material enables it to operate in high humidity environments without increased loss issues.

In the frequency range of microstrip microwave circuits, design performance is limited by conductor and dielectric loss. Conductor loss varies according to frequency and width, thickness, surface roughness, and height of the base plate. These factors are determined by design and generally do not change much in applications. Dielectric loss depends on the circuit layout, dielectric constant, frequency and tangent of loss angle. The dielectric constant and tangent value of loss angle vary with the working temperature and humidity level. For most PCB materials of PTFE, the dielectric constant is in the range of 100 C ( ε R) Values usually vary between 0 and 0.05%. However, the tangent of the loss angle (tan) δ) Great changes may occur, up to 200%, while the moisture absorption rate is only 0.25% of the dielectric weight. Reducing or eliminating the tangent change of the loss angle is a priority factor for reducing the overall circuit loss.

So far, most designs have compromised between high dielectric constant (RT / Duroid 6010 material) or low moisture absorptive PCB material (RT / Duroid 5880 material). High dielectric constant materials reduce space at the expense of higher moisture absorption levels. RT / Duroid 6010LM microwave PCB material bridges high ε R Ramp between low hygroscopic materials. RT / Duroid 6010LM microwave PCB material is a ceramic / PTFE composite material designed for microwave circuit applications requiring high dielectric constant and low hygroscopicity( ε R = 10.2 +0.25, Tan δ= 0.0028 (maximum), moisture absorption = 0.05% (typical value).

The results of a preliminary study comparing similar competing products ( ε R = 10.5 +0.25, Tan δ Less than 0.0027) For example Brand X and RT / Duroid 6010LM microwave PCB, the moisture absorption rate has an effect on the performance of the microwave PCB. Weight gain was measured on ten samples of each product. ε R and Tan δ. Experiments show that 0.25% water absorption makes ε R changes more than half the tolerance allowed.

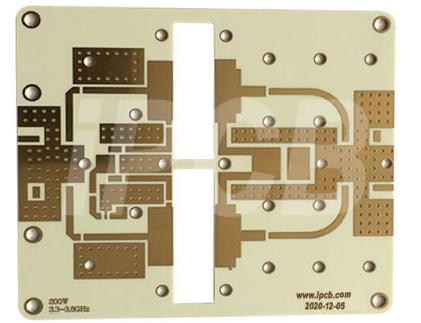

Absorption of water into the matrix significantly alters the loss of the system, which may make the circuit inoperable. To test these differences in practical applications, two band-pass filters were made, one using standard RT/duroid 6010 material with a water absorption similar to that of competing material products, and the second using RT/duroid 6010LM (selected to maintain the dielectric constant of two PCB materials of the same 10.2). RT/duroid 6010 LM material was compared with standard RT/duroid 6010. The response change due to adjustment is explained.

The effect of water on RT/duroid 6010LM Rogers PCB is converted to a 0.1 dB decrease in filter bandwidth and a 0.5 dB decrease in standard materials. This increased running loss may transition the filter from a correct operating state to an unacceptable range. The low hygroscopicity of the Rogers PCB RT/duroid 6010LM microwave PCB material enables it to operate in high humidity without loss increase and allows the designer to reduce the size of the circuit.