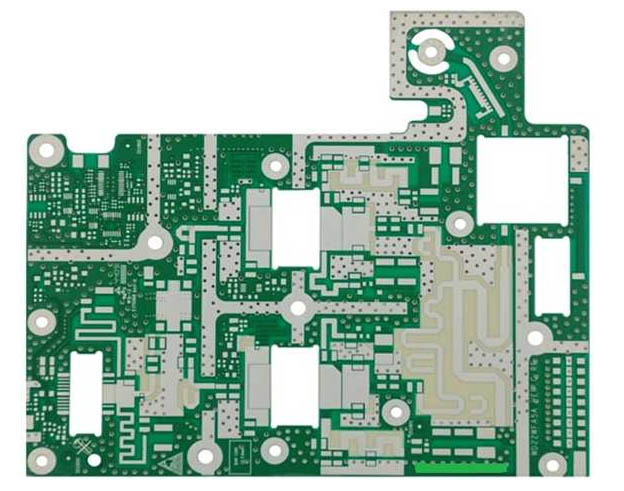

Rogers Ro4350B high-frequency PCB are glass fiber reinforced (non-PTFE) hydrocarbon/ceramic laminates designed for high volume, high-performance commercial applications. The Ro4350B is designed to provide superior RF performance and economical and efficient circuit production. The result is a low-loss material that can be produced at a competitive price using standard epoxy/glass (FR4) processes. As the operating frequency increases to 500 MHz or higher, the number of laminates that designers typically have to choose from is greatly reduced. The RO4350B PCB has the characteristics required by RF microwave developers to implement filters, coupled networks, and repeatable design impedance-controlled transmission lines for networks. The low dielectric loss allows the use of RO4350 series materials in many applications, where the higher operating frequency limits the use of laminated materials for traditional printed circuit boards. The temperature coefficient of the dielectric constant is one of the lowest of any printed circuit, and the dielectric constant is stable over a wide frequency range making it an ideal substrate for broadband applications.

Hole quality should be used to determine tool life rather than tool wear. The Roger RO4350B high-frequencyPCB provides good drilling quality when drilling with epoxy/glass standard drill bits. The roughness of the material holes RO4350B does not increase significantly when the tool is used compared to EP-OXy/glass. The typical values varied between 8 and 25 microns regardless of the number of visits (up to 8,000 visits were assessed). The roughness is directly related to the size of the ceramic filler and provides a favorable morphology for the adhesion of the pore wall. Drilling conditions for epoxy/glass plates have been found to have good hole quality and batting average over 2000.

Dimensional stability

This is a necessary characteristic for the construction of a hybrid dielectric multilayer plate. The low CTE of the RO4350B z-axis laminate provides reliable through-hole quality even in harsh thermal shock applications. The RO4350B series of materials have a TG in excess of 280°C (536°F), so their expansion properties remain stable at all process temperatures in the circuit. The RO4350B uses standard FR4 circuit board processing technology to easily convert a series of laminates to printed circuit boards. Unlike high-performance PTFE-based materials, RO4350B series laminates do not require special preparation processes such as sodium etching. This material is a rigid, heat-stable laminate that can be treated with automatic treatment systems and washers used to fabricate copper surfaces.

Availability

RO4350B laminates are currently available in a variety of 1080 and 1674 glass fabric models, all of which comply with the same laminated electrical performance specifications. Designed to be a direct replacement for RO4350B materials, the RO4350B laminates use a RoHS-compliant flame retardant technology for applications requiring UL 94V -0 certification. These materials meet the requirements of IPC4003/10 monolithic RO4003C and /11RO4350.

Preparation guide

RO4350B high-frequency circuit materials have been developed to provide high-frequency performance comparable to that of woven PTFE glass substrates, thus simplifying the manufacturing process of epoxy/glass laminates. RO4350B is a thermosetting material filled with hydrocarbon/glass fiber reinforced ceramics with very high glass transition temperatures (TG> 280 ° C). Unlike PTFE-based microwave materials, no special treatment or passing is required. As a result, the machining and assembly costs of RO4350B material circuit are comparable to that of epoxy/glass laminates.Here are some basic tips for handling the RO4350 two-sided printing plates. Typically, the parameters and treatment methods used for epoxy/glass plates can be used for RO4350B plates.

Input/output material

Inlet and outlet materials must be flat and hard to minimize copper burrs. Recommended input materials are aluminum and rigid composite panels (0.254 to 0.635 mm). Most conventional starting materials with or without aluminum coating are

suitable.

Maximum battery height

The thickness of the material to be drilled shall not exceed 70% of the length of the groove. This includes the thickness of the input material and penetration into the substrate.

Perforated

Surface speeds exceeding 500 SFM and chip loads less than 0.05mm (0.002 ") should be avoided whenever possible.

Coefficient of Thermal Expansion (CTE) RO4350B materials offer several key advantages to circuit designers. The expansion coefficient of the material RO4350B is similar to that of copper, which makes the material visible.