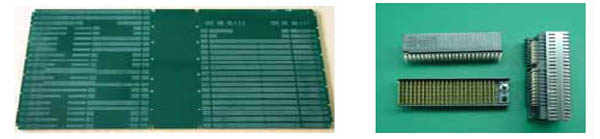

Product name: Плата объединительной платы связи

Material: isola 370hr

Df (dissipation factor): 0.021

Dk (dielectric constant): 4.04

Glass transition temperature: TG180℃

Td: 340℃

Number of Layers: 14 layers

Board thickness: 2.4mm

Surface technology: Immersion gold

Copper thickness: 1OZ

Minimum line width/line spacing: 6mil/6mil

Use: communication backplane pcb

The communication backplane PCB is made of isola 370hr material. The communication backplane bus is a high-speed data path between the PLC host and the I / O expansion module, supporting the I / O data refresh between the host and the expansion module. The technical level of backplane bus determines the I / O expansion ability of PLC products, это основная технология проектирования и изготовления PLC.

сейчас, the PCB board of PLC mostly uses isola 370hr material, and PLC mostly uses serial communication technology to realize backplane bus. Compared with parallel bus, serial bus has less leads and low hardware cost, и не легко быть помехой. Последовательные шины повышают надежность автоматизированного оборудования в плохих фабричных и промышленных условиях.

в области связи PCB широко применяются беспроводная сеть, сеть передачи данных, связь с данными и фиксированная широкополосная сеть. соответствующие продукты включают задней панели, высокоскоростные многослойные пластины, высокочастотные микроволновые пластины, многофункциональные металлические базы и так далее.

isola 370hr communication backplane pcb

In the field of communication PCB backplane board, около 85% потребностей в этой области обеспечены 13 крупными клиентами во всем мире. The certification of customers takes 2-3 years, and the threshold to enter the high-quality customer supply chain system is very high. At present, ipcb company has obtained the certification of many large-scale high-quality customers, and the top five customers such as mainland automotive electronics account for more than 50% of the company's revenue year after year. The company's supply to several core customers accounts for 10-20%. We believe that ipcb is expected to further increase this proportion to 25-35% by expanding its production capacity.

The projects raised by ipcb will gradually release production capacity. At present, the annual capacity of the company is 1.6 million square meters, and the capacity utilization rate has been maintained at a high level. It is estimated that the annual capacity utilization rate of this year will be more than 90%, which is basically full load production. The 750000 square meter HDI PCB expansion project in the project raised by ipcb company is currently in the stage of plant infrastructure construction. We expect to complete the construction of Q3 plant this year, пробный выпуск в первом квартале будущего года, and start to release production capacity in Q2 and Q3 next year. The 117300 3G communication high-end system PCB technology upgrading project invested by the fund mainly includes the reconstruction and expansion of the existing production line and the purchase of equipment. At present, a small part of the production capacity has been released, and we expect that the full release of the production capacity will be in the second half of next year.

ipcb's leading production scale, clear development ideas and good management level are the main factors to ensure the stable growth of ipcb in the future. ipcb company is currently in the forefront of the industry, but it has not yet achieved the absolute lead in PCB technology. сквозное расширение, it is expected to gradually become the leader in the field of communication backplane PCB. The raised investment projects have laid a good foundation for future capacity expansion.

Product name: Плата объединительной платы связи

Material: isola 370hr

Df (dissipation factor): 0.021

Dk (dielectric constant): 4.04

Glass transition temperature: TG180℃

Td: 340℃

Number of Layers: 14 layers

Board thickness: 2.4mm

Surface technology: Immersion gold

Copper thickness: 1OZ

Minimum line width/line spacing: 6mil/6mil

Use: communication backplane pcb

Что касается технических проблем PCB, то команда поддержки iPCB, обладающая обширными знаниями, поможет вам сделать каждый шаг. можно вас попросить PCB Вот цитата. Пожалуйста, свяжитесь по электронной почте sales@ipcb.com

мы будем быстро реагировать.